Coil Liner

Type: SDP 27 eLCQ41-CS

- Multi Lock external frame and heavy-duty rings for optimum strapping angle

- Forklift-compatible trough cover

- Coil troughs also for large coils with a diameter of 2,100 mm

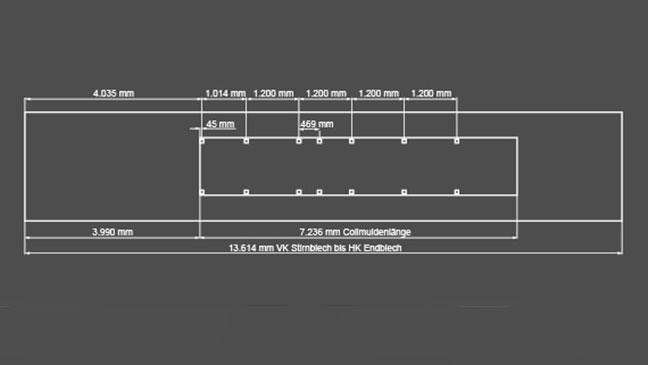

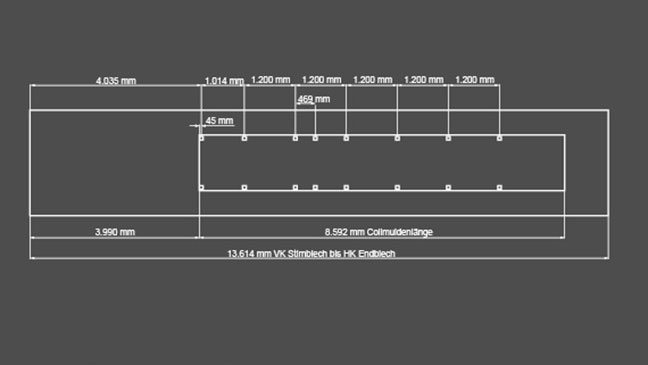

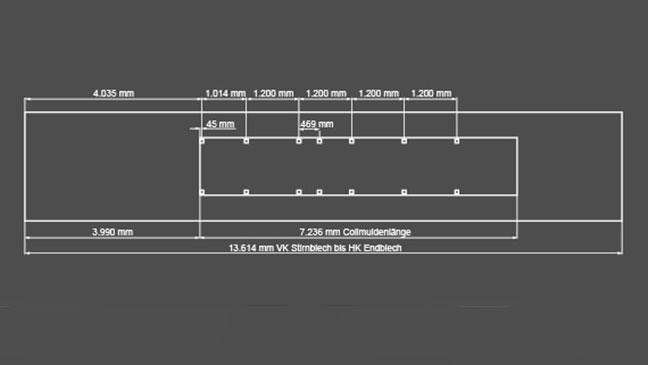

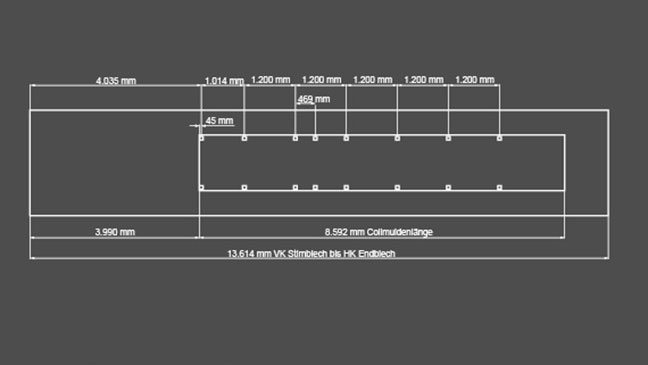

- Coil trough length 7.23 or 8.59 m available

- Also available as Coil Liner Ultra with 5,980 kg dead weight

The Coil Liner is distinguished by its many practical details. It features extremely robust chassis. In addition, its heavy-duty strapping rings on the external frame and additional plug-in posts allow steel coils to be secured in the best way possible.

Thanks to the Multi Lock external frame with a large number of lashing points and forklift-compatible coil covers, you can transport any load with the Coil Liner. It is load-independent certified.

Technical data

Type

SDP 27 eLCQ41-CS

Fifth-wheel load

12000 kg

Axle load

27000 kg

Permissible total weight

39000 kg

Dead weight

6830 kg

Unloaded fifth coupling height

1070 - 1250 mm

Payload (technically possible)

approx. 32170 kg

Axle distances

1410/1310 mm

Construction height, front

152 mm

Load compartment length

13620 mm

Load compartment width

2480 mm

Clear side height (lower edge of the external beam)

2000 - 2800 mm

Technical data

Type

SDP 27 eLCQ41-CS

Fifth-wheel load

12000 kg

Axle load

27000 kg

Permissible total weight

39000 kg

Dead weight

6830 kg

Unloaded fifth coupling height

1070 - 1250 mm

Payload (technically possible)

approx. 32170 kg

Axle distances

1410/1310 mm

Construction height, front

152 mm

Load compartment length

13620 mm

Load compartment width

2480 mm

Clear side height (lower edge of the external beam)

2000 - 2800 mm

Always a plus on equipment.

Simply inimitable

Robust spray guard

In the development of the mud flaps, special attention was paid to robust and practical design.

Solid three-part front wall

It is made of steel and firmly bolted to the frame. In case of emergency, it effectively braces against any load and therefore ensures excellent road safety. The roof height can be selected from 2,600 to 2,700 mm. With lifting roof equipment, from 2,595 to 2,845 mm, in 4 stages respectively.

Solid curtain tensioner

Integrated at a protected position at the rear, it provides sufficient leverage for a tightly fitted curtain. Our patented lifting aid on the curtain tensioning tube helps with unlocking the curtains.

Quick release curtain tensioner

Thanks to the clearly visible tensioning lever on the front wall, the curtains can also be quickly opened and closed from the front. On the front wall too, the patented lifting aid helps to unlock the curtains.

Comfortable sliding roof

A roof construction that amazes regularly with its ease of movement. The diagonal belts are integrated in the roof tarp and therefore provide space for loading. After loosening the curtain buckles, the sliding roof can also be opened from front to rear (optional) for overhead crane loading.

Practical centre posts

The sliding post can be easily operated using the single-lever control, which makes loading and unloading easier.

Protected valves

The setting valves are well protected behind the axle assembly. The wheel chocks, too, are easily accessible.

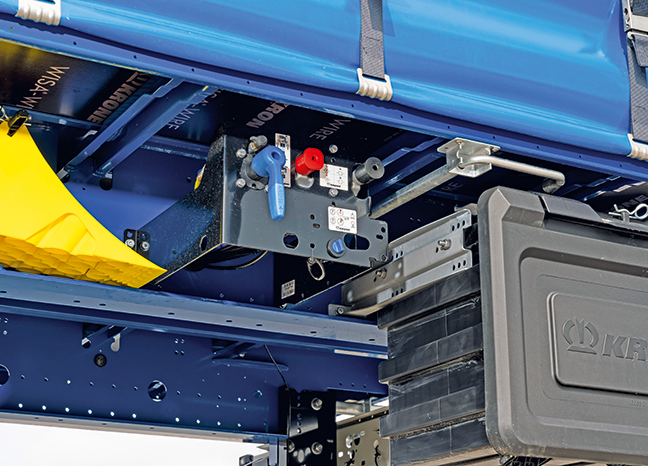

Solid coupling support

Electric and air connections are placed on two levels to prevent cables from snagging. The modular concept allows for any type of extension.

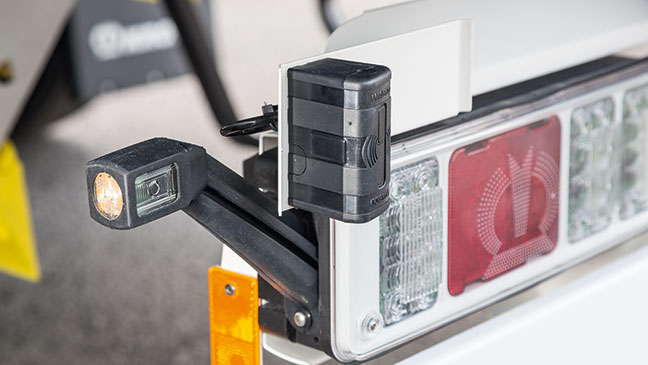

Protected lighting brackets

Underrun protection and the lighting brackets are fitted in a protected position and can be separately replaced. Robust ram protection elements protect the rear when docking.

Safe, telescopic ladder

Due to its large, conspicuous step, the stepladder ensures easy climbing and optimum safety. The ladder is riveted and easy to replace in case of damage.

Double collision protection

A chassis that is pulled up at the front and the bolted plywood rebound plate ensure double protection and stability.

Steel container doors manufactured by robots offer the highest level of quality and precision, with improved tightness.

Steel container doors manufactured by robots offer the highest level of quality and precision, with improved tightness.

Steel container doors manufactured by robots offer the highest level of quality and precision, with improved tightness.

Flashing side position lamps are fitted to prevent accidents when turning. It becomes much easier for pedestrians and cyclists to see when the HGV is about to turn.

Simple, but brilliant: The KRONE trough in the bottom of the Coil Liner blocks uncontrolled movements of the steel rolls

The Coil Liner also holds large coils with a diameter of 2,100 mm.

The Multi Lock external frame allows safety and down, direct and inclined strapping of coils in any direction

Ten pairs of heavy-duty strapping rings with a strapping load of 5,000 kg complement the many strapping points of the Multilock external frame. The strapping rings also have a cover at floor level to protect them from dirt when they are not being used.

The cover of the coil tub is easy to handle and so stable that it can also be easily driven over with forklifts (forklift axle load up to 5,460 kg).

The cover of the coil tub is easy to handle and so stable that it can also be easily driven over with forklifts (forklift axle load up to 5,460 kg).

Plug-in posts in the coil trough ensure a tight fit and the correct load distribution. Two plug-in posts (80 x 80 mm) are standard. Others are available as options.

The Coil Liner is available with two different trough lengths: 7.23 (standard) or 8.59 m (option)

The Coil Liner is available with two different trough lengths: 7.23 (standard) or 8.59 m (option)

Steel container doors manufactured by robots

Steel container doors manufactured by robots offer the highest level of quality and precision, with improved tightness.

Flashing side position lamps

Flashing side position lamps are fitted to prevent accidents when turning. It becomes much easier for pedestrians and cyclists to see when the HGV is about to turn.

Safe coil well

Simple, but brilliant: The KRONE trough in the bottom of the Coil Liner blocks uncontrolled movements of the steel rolls

Large coils up to 2,100 mm

The Coil Liner also holds large coils with a diameter of 2,100 mm.

Optimum strapping angle

The Multi Lock external frame allows safety and down, direct and inclined strapping of coils in any direction

Heavy-duty strapping rings

Ten pairs of heavy-duty strapping rings with a strapping load of 5,000 kg complement the many strapping points of the Multilock external frame. The strapping rings also have a cover at floor level to protect them from dirt when they are not being used.

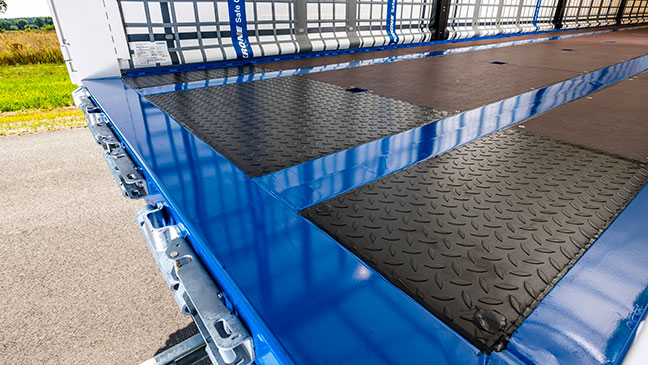

Robust trough cover

The cover of the coil tub is easy to handle and so stable that it can also be easily driven over with forklifts (forklift axle load up to 5,460 kg).

Stable plug-in posts

Plug-in posts in the coil trough ensure a tight fit and the correct load distribution. Two plug-in posts (80 x 80 mm) are standard. Others are available as options.

Trough position

The Coil Liner is available with two different trough lengths: 7.23 (standard) or 8.59 m (option)

Additional storage space

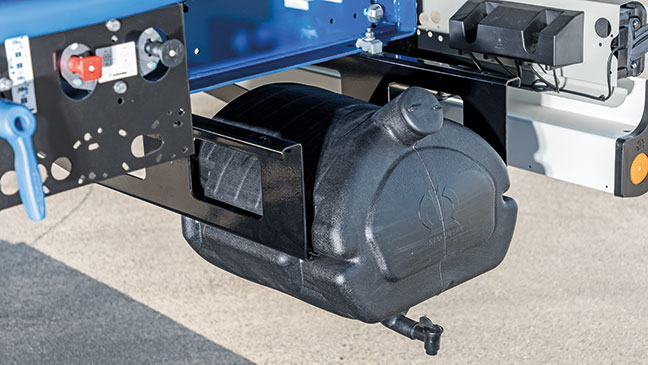

The Dakenbox is also made of plastic. It offers you a larger stowage space when compared to conventional tool boxes. Surface load 70 kg (dimensions: approx. 1030 x 500 x 480 mm).

The big plastic toolbox constructed of shock-resistant material is attached to the frame with sturdy crossbeams. Surface load 50 kg (dimensions: approx. 650 x 490 x 450 mm)

As an alternative to the plastic toolbox, KRONE also offers a version made from galvanized steel with painted lid.

The document box for vehicle documents is installed conveniently accessible on the front wall.

On request, we can provide you with a storage box that is practically integrated in the spare wheel bracket.

The lath depot below the chassis accommodates wooden or aluminium plug-in planks.

An open depot located laterally below the chassis holds the plug-in posts when not in use.

The plug-in posts are stored in a closed stow box mounted transversely under the chassis to prevent theft and contamination.

Storage box and fire extinguisher (6 kg) are mounted within easy reach on the landing leg winches. Alternatively, the boxes can also be attached to the front wall.

Storage box and fire extinguisher (6 kg) are mounted within easy reach on the landing leg winches. Alternatively, the boxes can also be attached to the front wall.

An optional 50-litre water tank ensures availability of fresh water.

Chassis and running gear

Lift axles automatically respond load-dependently. This allows you to reduce your tyre wear and save fuel.

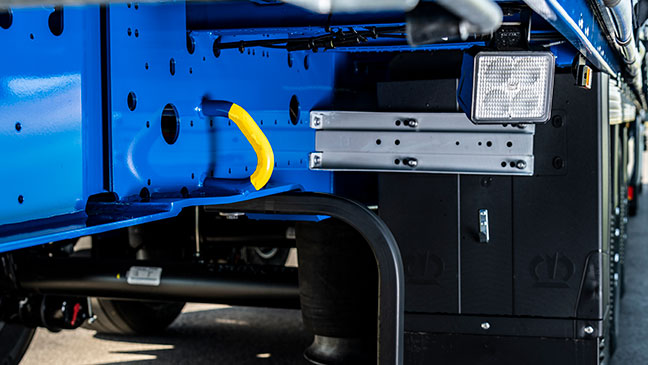

A yellow beacon and a pull-out warning sign warns other participants in road traffic, e.g., when transporting extra-wide loads.

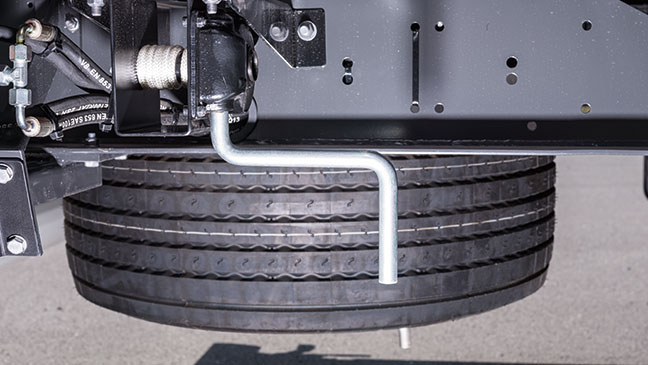

The spare wheel is stored in the middle. The easily accessible screw connection also allows a rim to be secured.

For low coupling heights, a spare wheel holder can be used as a winch.

An optional spray suppressor minimises rear water spray for following traffic.

Stable ferry rings secure the vehicle in ferry traffic.

Additional air connections are also available for international traffic with changing tractor units (here: DANA C).

The Duomatic quick coupling permits an uncomplicated coupling of the air lines.

You can determine the effective mileage of your vehicle independently of the tractor unit using an axle cap KM counter.

State-of-the-art reversing devices, such as Soft Docking or Tailguard, help you avoid damage when docking at the ramp.

State-of-the-art reversing devices, such as Soft Docking or Tailguard, help you avoid damage when docking at the ramp.

An additional work light below the chassis on the side makes work easier when visibility is poor.

Superstructure

Solid wood floors longitudinally installed between the main beams with edging made of omega profiles, 40 mm thick.

Floor reinforcement at the rear using checker plate, the ideal reinforcement for hard forklift operations on the ramp.

Roller bumpers as an alternative collision protection. The hard rubber rollers also compensate for variable loading dock heights.

KRONE offers protection equipment to prevent water and ice plate build-up on the vehicle roof. Ice-Protect Air operates via an air hose between the roof tarp and the transverse hoop. The on-board compressed air system supplies the air. The roof tarp is raised by roughly 175 mm to form a saddle roof.

KRONE offers protection equipment to prevent water and ice plate build-up on the vehicle roof. Ice-Protect Air operates via an air hose between the roof tarp and the transverse hoop. The on-board compressed air system supplies the air. The roof tarp is raised by roughly 175 mm to form a saddle roof.

A strap holder, which is bolted to the transverse hoop of the roof, facilitates load securing. After loading, the piece of hose gives way when pulled - the driver no longer has to struggle to pull the belts over.

A bent steel profile on the rear frame protects the turn rod lock effectively.

Extended steel frame corners ensure additional protection when docking.

Adapt the ram protection to meet your requirements. Our modular ram buffer product range offers a multitude of possibilities, whether it be with steel or rubber ram buffers. You can choose the quantity and their shape.

A double bulkhead in the front allows for even positioning of pallets and mesh boxes during loading and protecting the bulkhead from excessive wear during heavy-duty automotive use.

Tarpaulin equipment

With Krone's new load securing curtain Safe Curtain, high-strength spring steel strips are integrated in vertical PVC tunnel pockets in the side curtains. With this technology, Krone offers you a load securing system per side curtain for stable loading, in which there is no need for the classic plug-in planks. The advantage: Handling the Safe Curtain is not only simpler, safer and quicker, but – compared to conventional side curtains with plug-in planks – there are also weight savings of roughly 90 kg. The new safety curtain can be retrofitted on all conventional KRONE sliding curtain semitrailers. The Safe Curtain is certified according to DIN EN 12642 Code XL (up to 140 km/h), VDI 2700 ff beverage certificate and Daimler 9.5. The rearward load securing on the semitrailer is still possible using locking bars.

Another advantage: the integrated spring steel strips also take over an anti-theft function in the vertical direction: If the curtain is deliberately cut, it is only possible to cut to the next spring steel strip. Repairing the curtain is also just as simple as with a standard side curtain. In addition, work-related accidents caused by falling plug-in laths are a thing of the past.

With Krone's new load securing curtain Safe Curtain, high-strength spring steel strips are integrated in vertical PVC tunnel pockets in the side curtains. With this technology, Krone offers you a load securing system per side curtain for stable loading, in which there is no need for the classic plug-in planks. The advantage: Handling the Safe Curtain is not only simpler, safer and quicker, but – compared to conventional side curtains with plug-in planks – there are also weight savings of roughly 90 kg. The new safety curtain can be retrofitted on all conventional KRONE sliding curtain semitrailers. The Safe Curtain is certified according to DIN EN 12642 Code XL (up to 140 km/h), VDI 2700 ff beverage certificate and Daimler 9.5. The rearward load securing on the semitrailer is still possible using locking bars.

Another advantage: the integrated spring steel strips also take over an anti-theft function in the vertical direction: If the curtain is deliberately cut, it is only possible to cut to the next spring steel strip. Repairing the curtain is also just as simple as with a standard side curtain. In addition, work-related accidents caused by falling plug-in laths are a thing of the past.

KRONE uses elbowed curtain rollers for a majority of the sliding curtains. This reduces the resistance of the rollers on the rubber sealing lip, which makes it easy to handle the curtain when opening and closing it.

Tarpaulin with rubber expanders (zigzag), curtain cramps in closed R-design.

Retractable tarpaulin with rubber expanders (zigzag), curtain cramps in closed R-design.

As an alternative to the locking eyelet on cramp, an aluminium profile can also be integrated in the curtain pocket where conventional curtain tensioners can be hooked into.

Naturally, the sliding curtain superstructure also comes with additional side board walls.

Latch-type safety lock ratchet, suitable for use on trains with belt brakes.

Tilt safety lock ratchet, suitable for use on trains with belt brakes.

Knee lever curtain tensioner.

Load securing and anti-theft curtain. Rectangular steel ropes woven on the inside provide anti-theft protection.

As an additional alternative, a curtain with internally welded-on steel ropes is also available.

The Guard Curtain can also be used on the roof with its welded-on steel ropes.

As an additional alternative, a curtain with internally welded-on steel ropes is also available.

The Guard Curtain can also be used on the roof with its welded-on steel ropes.

The Safe Curtain tarpaulin can also be supplemented with additional welded-on steel ropes, which in turn offers increased protection against theft.

Load securing

Fewer belts or doing without anti-slip mats - This is possible using a special spray coating that is applied to the conventional floor plates with a coating thickness of approx. 4 mm. In addition to the time saved while securing the load (coefficient of kinetic friction of 0.6), this also significantly reduces the noise produced during loading.

The AJ system offers a wide range of securing options. Steel plug-in planks accommodate a wide range of elements: Locking bars for securing the load at the rear, lath sockets that can be positioned as required to accommodate plug-in planks in the transverse direction, straps for securing individual cargo items in the longitudinal direction.

The AJ system offers a wide range of securing options. Steel plug-in planks accommodate a wide range of elements: Locking bars for securing the load at the rear, lath sockets that can be positioned as required to accommodate plug-in planks in the transverse direction, straps for securing individual cargo items in the longitudinal direction.

The AJ system offers a wide range of securing options. Steel plug-in planks accommodate a wide range of elements: Locking bars for securing the load at the rear, lath sockets that can be positioned as required to accommodate plug-in planks in the transverse direction, straps for securing individual cargo items in the longitudinal direction.

Galvanised plug-in posts (80 x 80 mm) for post sockets in the floor are especially used for securing loads of sawn timber. Stable plastic filling pieces prevent dirt ingress when not in use.

Galvanised plug-in posts (80 x 80 mm) for post sockets in the floor are especially used for securing loads of sawn timber. Stable plastic filling pieces prevent dirt ingress when not in use.

The screw-fastened pallet stop elements can be quickly and securely bolted to the external frame.

An additional attachment on the external frame prevents bending of the lower plug-in planks and provides safe collision protection. In addition, this solution is an alternative for the pallet stops required for the Daimler Certification 9.5.

Multi Strap is a tension strap system that can be slid over the entire length of the load, making it considerably easier for the driver to use tension straps for load securing. The straps, held in a special bogie truck under the roof of the trailer, can be quickly moved from the ground to the required position via a traction device. One-sided opening of the sliding curtain suffices in this regard. After loading, the tension straps are immediately available and can be promptly secured. Straps that are not needed can be parked on the front wall behind a holder to save space, thus the cargo area remains freely accessible. After loosening the tension straps, they are pulled back into their park position underneath the roof by bungee cords. The maximum loading width remains always available. After unloading, the tension straps no longer need to be rolled up and stowed, and they are quickly ready for the next use.

Multi Strap is a tension strap system that can be slid over the entire length of the load, making it considerably easier for the driver to use tension straps for load securing. The straps, held in a special bogie truck under the roof of the trailer, can be quickly moved from the ground to the required position via a traction device. One-sided opening of the sliding curtain suffices in this regard. After loading, the tension straps are immediately available and can be promptly secured. Straps that are not needed can be parked on the front wall behind a holder to save space, thus the cargo area remains freely accessible. After loosening the tension straps, they are pulled back into their park position underneath the roof by bungee cords. The maximum loading width remains always available. After unloading, the tension straps no longer need to be rolled up and stowed, and they are quickly ready for the next use.

Steel plug-in planks with locking beams for securing loads to the rear.

Alternatively, there are width-adjustable clamping beams.

To secure beverage crates and beverage pallets, the laths can be inserted horizontally or vertically into the lath sockets.

Steel plug-in planks and locking bars are also used for securing Octabins. The reversing laths ensure a tight fit on either side.

The welded-on pallet stop edge facilitates loading and prevents the load from slipping.

Telematics

KRONE's award-winning 3D telematics is the next evolutionary step in trailer telematics. Starting with the first dimension, KRONE offers high precision through its advanced telematics hardware and telematics portal. This allows customers to see exactly where their vehicles are. KRONE, a trailer manufacturer with years of expertise, offers a virtual twin of the trailer with all relevant data to support customers in their daily operations.

learn moreWarranty

Each new KRONE vehicle is delivered with a manufacturer's warranty. Our KRONE warranty extension allows you to extend the warranty period up to four years, because we are absolutely convinced of the quality of our vehicles. You can add this option directly at the time of purchase or in the following three months. The KRONE warranty extension can be purchased with Fair Care Complete.

learn moreSpare parts shop

The KRONE spare parts service - carriers must face many challenges and meet the highest standards of quality, reliability and care of a vehicle manufacturer as well as their products and services. KRONE considers service to be an obligation that does not end at the factory gate. At www.krone-trailerparts.com, you will find many accessories for your trailer, ranging from KRONE axle accessories to tool boxes.

learn moreFair Care

Planning and carrying out maintenance and wear-related repairs are time-consuming. Our Fair Care Service takes this work off your hands. Customise your individual service package for maintenance and wear-related repairs according to your needs, available with a term of 24 or up to 72 months. Depending on the contract module purchased, your KRONE Fair Care services include comprehensive services, such as vehicle maintenance including the replacement of wear parts, technical maintenance and the 24-hour breakdown service available in many countries.

learn moreFinancing

In logistics, flexibility is the decisive market advantage. This also applies to liquidity. That is why we offer you customised financing models, such as leasing, hire purchase or investment credit. You can easily increase your financial leeway when you need it.

learn more

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/5/csm_krone-megai-liner-comfort-freisteller_cd7ff2acaf.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/e/csm_krone-coil-compact-freisteller_a42a8fa25e.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/2/8/csm_krone-cool_liner_multitemp_freisteller_f9f7155d84.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/e/csm_krone-cool_liner_doppelstock_freisteller_4bf611bc7a.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/c/e/csm_krone-cool_liner_meathang_freisteller_df1c23c5a3.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/0/csm_krone_trailer_box_liner_eltu5_plus_fd6f92c531.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/1/csm_krone_trailer_box_liner_eltu5_2_1e7fc86956.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/4/csm_krone_trailer_box_liner_eltu4_a03c3c83c5.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/d/csm_krone-box-liner-sdc-27-el40_04b540a68b.png)

![[Translate to EN:] Profi Liner [Translate to EN:] Profi Liner](/fileadmin/_processed_/9/b/csm_krone-profi-liner-sdp-27-elb50-cs_47b1772edf.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/5/csm_krone-megai-liner-comfort-freisteller_dead48ff41.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/e/csm_krone-coil-compact-freisteller_7e5f848a56.png)

![[Translate to EN:] Paper Liner [Translate to EN:] Paper Liner](/fileadmin/_processed_/0/1/csm_krone-paper-liner-freisteller_9bcbed63da.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/5/csm_krone-multi-steel-freisteller_22526b58b8.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/d/9/csm_krone-profi-liner-hd-freisteller_4c2435b435.png)