Box Carrier

The swap trailer from Krone

- Robust and torsion-resistant for high swap cycles

- Optimum driving characteristics

- Easy handling

- Extensive solutions for all parking heights

- KTL priming and powder-coated

Changing load units requires efficient solutions. KRONE's swap trailers meet the requirements of an economic transport workflow. They are extraordinarily robust and therefore specifically designed for the hard day-to-day business with high swap cycles.

Technical data

Type

AZW 18 eL3B9

Axle load

18000 kg

Permitted total weight

18000 kg

Approx. dead weight:

2570 kg

Payload (without load carrier)

15280 kg

Wheelbase

5170 mm

Total length (up to the centre of the coupling ring)

9045 mm

Draw fork length

2200 mm

Locking distance

5853 mm

Standard stop up to front lock

800 mm

Frame height, unloaded + lowered

1190 mm

Frame height, unloaded + lifted

1370 mm

Frame height, unloaded in driving position

1255 mm

Parking level

1220-1320 mm

Technical data

Type

AZW 18 eL3B9

Axle load

18000 kg

Permitted total weight

18000 kg

Approx. dead weight:

2570 kg

Payload (without load carrier)

15280 kg

Wheelbase

5170 mm

Total length (up to the centre of the coupling ring)

9045 mm

Draw fork length

2200 mm

Locking distance

5853 mm

Standard stop up to front lock

800 mm

Frame height, unloaded + lowered

1190 mm

Frame height, unloaded + lifted

1370 mm

Frame height, unloaded in driving position

1255 mm

Parking level

1220-1320 mm

Always a plus on equipment.

Simply inimitable

Box Carrier B9

The Profi Box Carrier B9 is designed for a parking level of 1,220 and 1,320 mm, which is the standard for swap body transport.

Mega Box Carrier as a central axle

The Mega Box Carrier as a central axle type is designed for transporting high-volume swap bodies. It has been dimensioned for parking levels of 920- 1070 mm.

Box Carrier B7

The Profi Box Carrier B7 is also designed for transporting high-volume swap bodies. It has been dimensioned for parking levels of 1,020 to 1,320 mm.

Multi Box Carrier E13

The E13 Multi Box Carrier is fitted with a height-adjustable locking system. It has been dimensioned for parking levels of 890 to 1,320 mm.

Functional guide tunnel

Guide tunnel that is bevelled at the front on the swap body facilitates the retraction of the centring rollers and reduces damage during superstructure change routines.

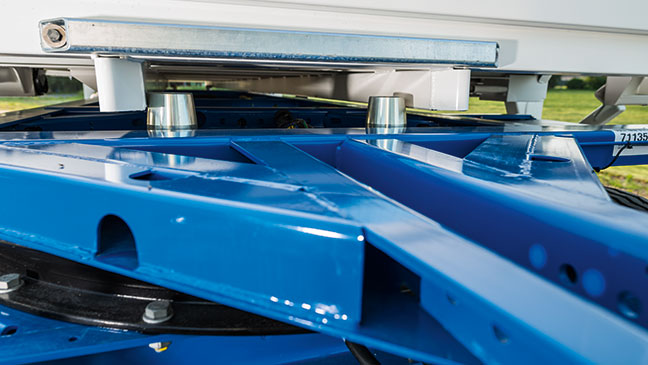

Centring roller parking position

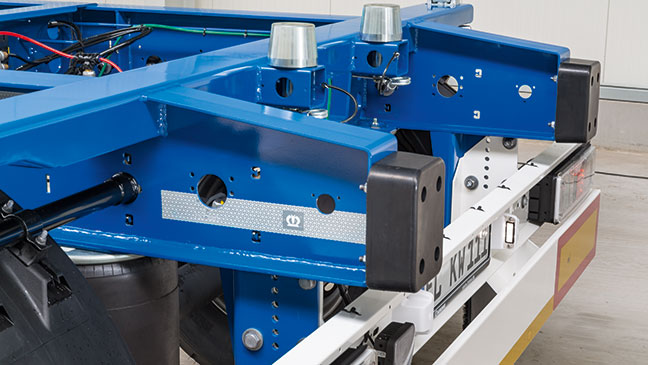

The additional parking position for the centring rollers allows ISO containers to be seated.

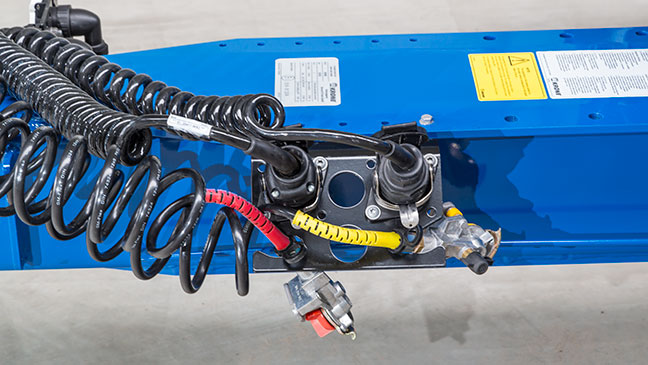

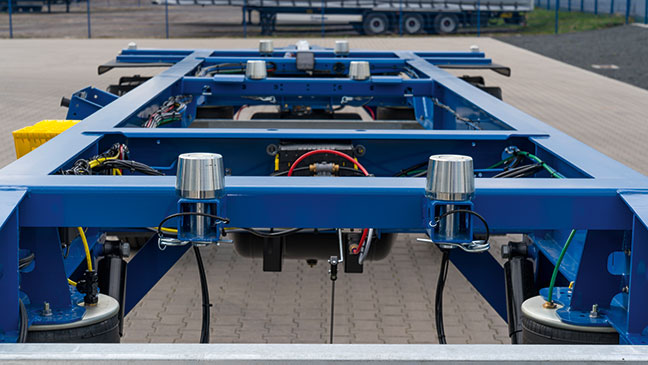

Clearly arranged lines

The use of blind boxes for the connection lines prevents damage to connection cables which fall down.

Sophisticated connection solution

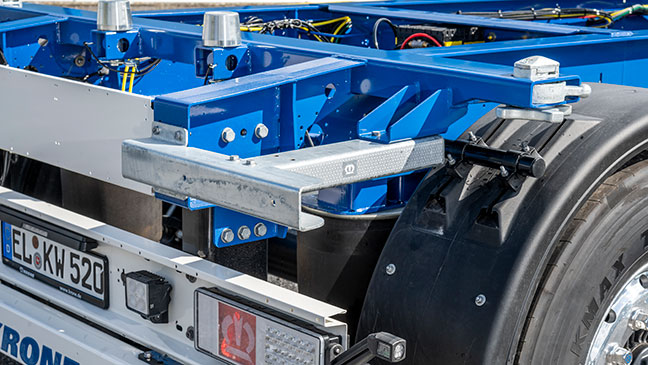

The slants of the longitudinal beams at the rear facilitate connection on uneven ground if the centring tunnels of the platforms are lower than is possible for the chassis frame to enter.

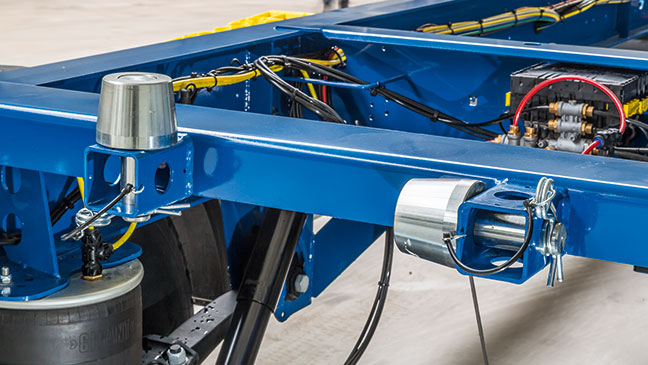

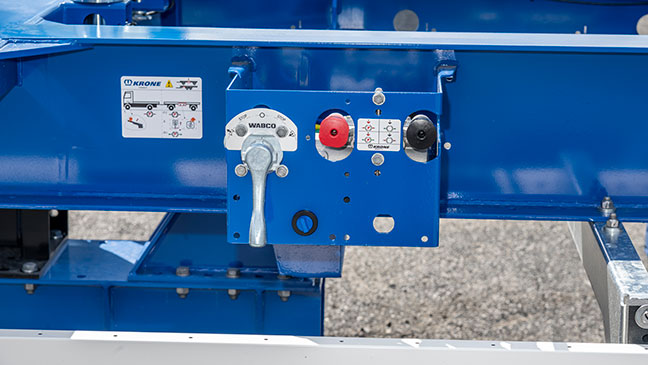

Control console with raising and lowering valves

With 2-axle swap body trailers with turn frame, the front and rear axles can be controlled separately using two raising and lowering valves.

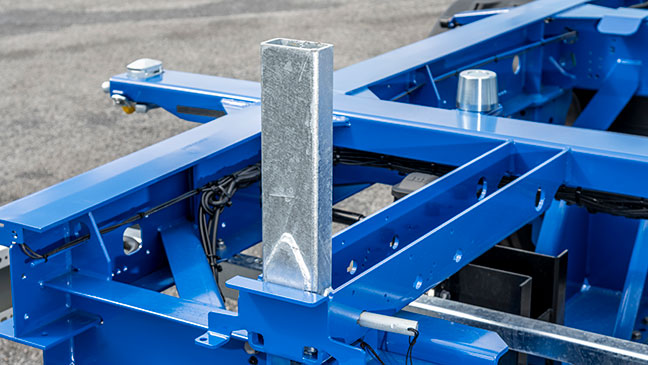

Stops for different bridge lengths

The use of folding stops allows a perfect fit between the swap container and the semitrailer.

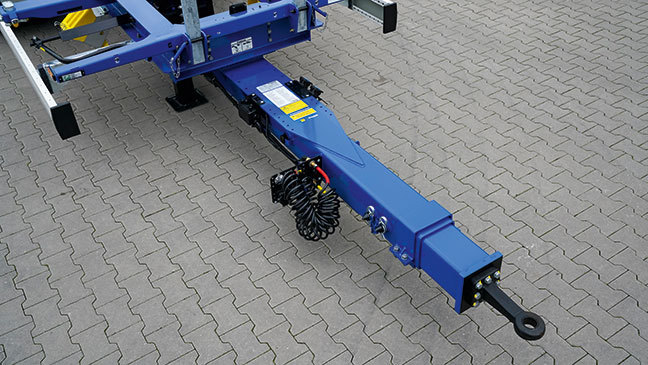

Low-maintenance live ring

Low-maintenance ball-type live ring and draw fork with silent bushings and height adjustment device in accordance with UVV (accident prevention regulations).

Twist locks

All swap body trailers have easy-to-use twist locks, which are manufactured in large series by well-known manufacturers.

Optional equipment Swap body trailers

Accompanying documentation can be safely transported in a protected documentation tube.

The central axle trailer with height-adjustable twist locks and hinged shims is suitable for changing transport tasks of volume and standard semitrailers.

Swivel and drop landing legs at the rear with high ground clearance while driving are used to support the vehicle when loading/unloading from the rear. Alternatively, landing legs with a crank system on both sides are available.

Swivel and drop landing legs at the rear with high ground clearance while driving are used to support the vehicle when loading/unloading from the rear. Alternatively, landing legs with a crank system on both sides are available.

Swivel and drop landing legs at the rear with high ground clearance while driving are used to support the vehicle when loading/unloading from the rear. Alternatively, landing legs with a crank system on both sides are available.

Swivel and drop landing legs at the rear with high ground clearance while driving are used to support the vehicle when loading/unloading from the rear. Alternatively, landing legs with a crank system on both sides are available.

Swap bridge trailers for volume swap bridges can be delivered fitted with a spare wheel bracket with a winch.

It is equipped with a working light (behind the slewing ring in this case), which facilitates the superstructure change routine in poor visibility conditions.

The telescopic draw fork for different coupling rebounds on tractor units (optional).

The length-adjustable drawbar wale can be adjusted to different coupling rebounds on the HGV.

The length-adjustable drawbar wale can be adjusted to different coupling rebounds on the HGV.

Alternatively, the swap body trailer can be equipped with a ramp collision protection as a sturdy steel beam (full-length or on the left and right).

Alternatively, the swap body trailer can be equipped with a ramp collision protection as a sturdy steel beam (full-length or on the left and right).

Additional centring rollers are available as an option to facilitate platform procedures by ensuring a better guiding function.

Telematics

KRONE's award-winning 3D telematics is the next evolutionary step in trailer telematics. Starting with the first dimension, KRONE offers high precision through its advanced telematics hardware and telematics portal. This allows customers to see exactly where their vehicles are. KRONE, a trailer manufacturer with years of expertise, offers a virtual twin of the trailer with all relevant data to support customers in their daily operations.

learn moreWarranty

Each new KRONE vehicle is delivered with a manufacturer's warranty. Our KRONE warranty extension allows you to extend the warranty period up to four years, because we are absolutely convinced of the quality of our vehicles. You can add this option directly at the time of purchase or in the following three months. The KRONE warranty extension can be purchased with Fair Care Complete.

learn moreFair Care

Planning and carrying out maintenance and wear-related repairs are time-consuming. Our Fair Care Service takes this work off your hands. Customise your individual service package for maintenance and wear-related repairs according to your needs, available with a term of 24 or up to 72 months. Depending on the contract module purchased, your KRONE Fair Care services include comprehensive services, such as vehicle maintenance including the replacement of wear parts, technical maintenance and the 24-hour breakdown service available in many countries.

learn moreFinancing

In logistics, flexibility is the decisive market advantage. This also applies to liquidity. That is why we offer you customised financing models, such as leasing, hire purchase or investment credit. You can easily increase your financial leeway when you need it.

learn moreSpare parts shop

The KRONE spare parts service - carriers must face many challenges and meet the highest standards of quality, reliability and care of a vehicle manufacturer as well as their products and services. KRONE considers service to be an obligation that does not end at the factory gate. At www.krone-trailerparts.com, you will find many accessories for your trailer, ranging from KRONE axle accessories to tool boxes.

learn more

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/5/csm_krone-megai-liner-comfort-freisteller_cd7ff2acaf.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/e/csm_krone-coil-compact-freisteller_a42a8fa25e.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/2/8/csm_krone-cool_liner_multitemp_freisteller_f9f7155d84.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/e/csm_krone-cool_liner_doppelstock_freisteller_4bf611bc7a.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/c/e/csm_krone-cool_liner_meathang_freisteller_df1c23c5a3.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/0/csm_krone_trailer_box_liner_eltu5_plus_fd6f92c531.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/1/csm_krone_trailer_box_liner_eltu5_2_1e7fc86956.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/4/csm_krone_trailer_box_liner_eltu4_a03c3c83c5.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/d/csm_krone-box-liner-sdc-27-el40_04b540a68b.png)