![[Translate to EN:] [Translate to EN:]](/fileadmin/media/productimages/standardproducts/coil_liner_compact/krone-coil-compact-freisteller.png)

Coil Liner Compact

Type: SDP 27 eLCC10-CS

- Specialist for coil and slit strip transport

- High payload thanks to a dead weight of only 4,999 kg

- Multi Lock external frame and heavy-duty rings for optimum strapping angle

- Vario Coil System for optimum coil protection

- Eight pairs of heavy-duty strapping rings each with a strapping load of 5,000 kg

The specialist:

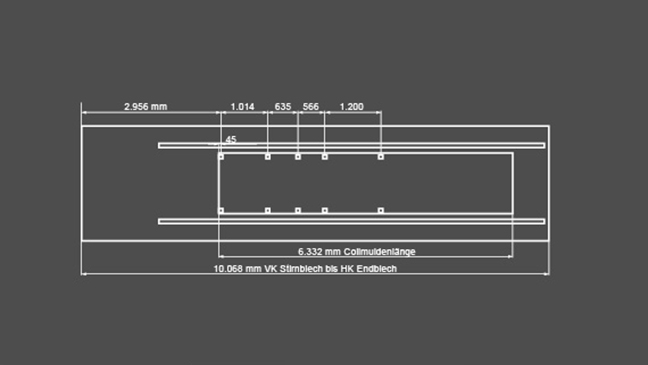

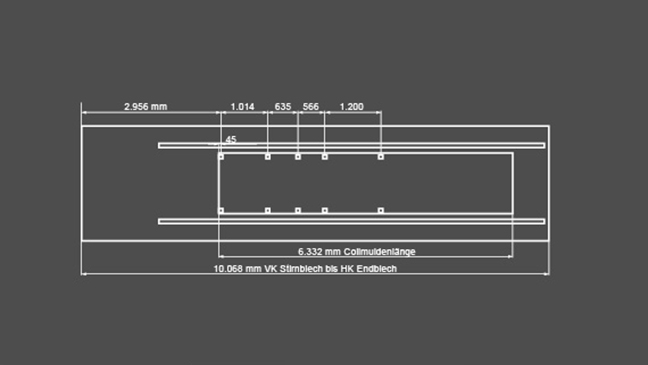

10 m vehicle length and 6.3 m coil trough with a dead weight of 4,999 kg: This data makes the Coil Liner Compact a specialist for transporting coils and slit strips. The new Vario Coil system makes load securing easier. Five pairs of post sockets in the coil well and two plug-in posts are included in the standard equipment.

Technical data

Type

SDP 27 eLCC10-CS

Fifth-wheel load

14000 kg

Axle load

27000 kg

Permissible total weight

41000 kg

Dead weight

4999 kg

Unloaded fifth coupling height

1050 - 1250 mm

Payload (technically possible)

approx. 36001 kg

Axle distances

1410/1310 mm

Construction height, front

180 mm

Load compartment length

10068 mm

Load compartment width

2480 mm

Clear side height (lower edge of the external beam)

2300 - 2400 mm

![[Translate to EN:] [Translate to EN:]](/fileadmin/media/productimages/standardproducts/coil_liner_compact/krone-coil-compact-freisteller.png)

Technical data

Type

SDP 27 eLCC10-CS

Fifth-wheel load

14000 kg

Axle load

27000 kg

Permissible total weight

41000 kg

Dead weight

4999 kg

Unloaded fifth coupling height

1050 - 1250 mm

Payload (technically possible)

approx. 36001 kg

Axle distances

1410/1310 mm

Construction height, front

180 mm

Load compartment length

10068 mm

Load compartment width

2480 mm

Clear side height (lower edge of the external beam)

2300 - 2400 mm

Always a plus on equipment.

Simply inimitable

Robust spray guard

In the development of the mud flaps, special attention was paid to robust and practical design.

Double collision protection

A chassis that is pulled up at the front and the bolted plywood rebound plate ensure double protection and stability.

Solid three-part front wall

It is made of steel and firmly bolted to the frame. In case of emergency, it effectively braces against any load and therefore ensures excellent road safety. The roof height can be selected from 2,600 to 2,700 mm. With lifting roof equipment, from 2,595 to 2,845 mm, in 4 stages respectively.

Solid curtain tensioner

Integrated at a protected position at the rear, it provides sufficient leverage for a tightly fitted curtain. Our patented lifting aid on the curtain tensioning tube helps with unlocking the curtains.

Quick release curtain tensioner

Thanks to the clearly visible tensioning lever on the front wall, the curtains can also be quickly opened and closed from the front. On the front wall too, the patented lifting aid helps to unlock the curtains.

Comfortable sliding roof

A roof construction that amazes regularly with its ease of movement. The diagonal belts are integrated in the roof tarp and therefore provide space for loading. After loosening the curtain buckles, the sliding roof can also be opened from front to rear (optional) for overhead crane loading.

Practical centre posts

The sliding post can be easily operated using the single-lever control, which makes loading and unloading easier.

Protected valves

The setting valves are well protected behind the axle assembly. The wheel chocks, too, are easily accessible.

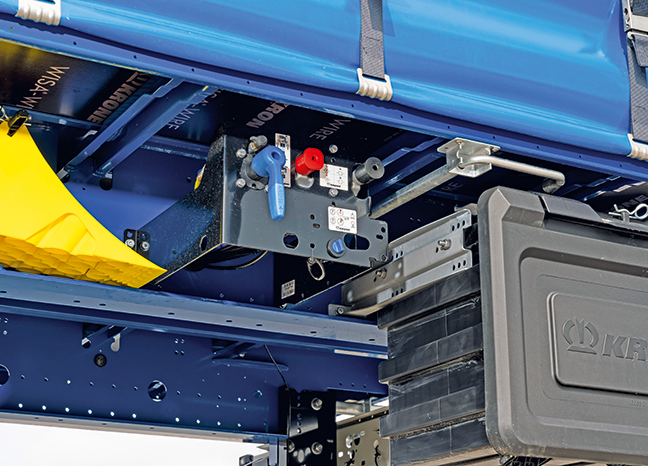

Solid coupling support

Electric and air connections are placed on two levels to prevent cables from snagging. The modular concept allows for any type of extension.

Protected lighting brackets

Underrun protection and the lighting brackets are fitted in a protected position and can be separately replaced. Robust ram protection elements protect the rear when docking.

Safe, telescopic ladder

Due to its large, conspicuous step, the stepladder ensures easy climbing and optimum safety. The ladder is riveted and easy to replace in case of damage.

Underrun protection and light panels as individual components.

The separate and screwed-on execution of the components. Separately bolted and screwed components allow for easy replacement.

Using a grid rail on the beams along the coil trough, the Vario Coil system can be inserted flexibly along the whole length. This means that coils and slit strips of any size can be secured at the load's centre of gravity. Two coil securing supports with struts support the coil in the forwards direction , while one beam behind the coil secures it rearwards with the use of tension chains.

Using a grid rail on the beams along the coil trough, the Vario Coil system can be inserted flexibly along the whole length. This means that coils and slit strips of any size can be secured at the load's centre of gravity. Two coil securing supports with struts support the coil in the forwards direction , while one beam behind the coil secures it rearwards with the use of tension chains.

Using a grid rail on the beams along the coil trough, the Vario Coil system can be inserted flexibly along the whole length. This means that coils and slit strips of any size can be secured at the load's centre of gravity. Two coil securing supports with struts support the coil in the forwards direction , while one beam behind the coil secures it rearwards with the use of tension chains.

Using a grid rail on the beams along the coil trough, the Vario Coil system can be inserted flexibly along the whole length. This means that coils and slit strips of any size can be secured at the load's centre of gravity. Two coil securing supports with struts support the coil in the forwards direction , while one beam behind the coil secures it rearwards with the use of tension chains.

An optimised chassis, winchable aluminium landing legs and air tanks give the vehicle its low dead weight of 4,999 kg.

Eight pairs of Heavy-duty strapping rings with a strapping load of 5,000 kg complement the many strapping points of the Multilock external frame

In the neck area, the vehicle is fitted with additional post sockets as well as heavy-duty strapping rings. The front wall is clear to allow side loading

The Coil Liner Compact can be fitted with a curtain roller to open the rear of the vehicle more quickly.

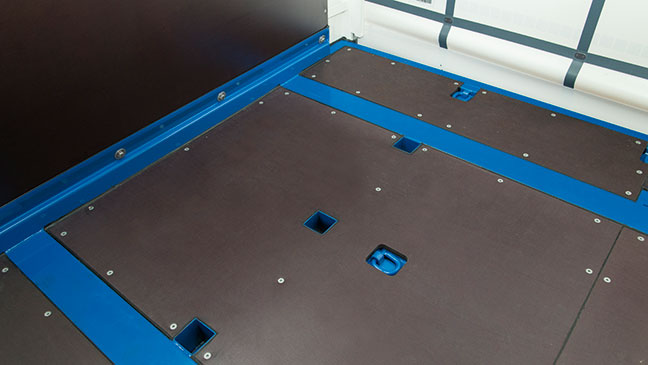

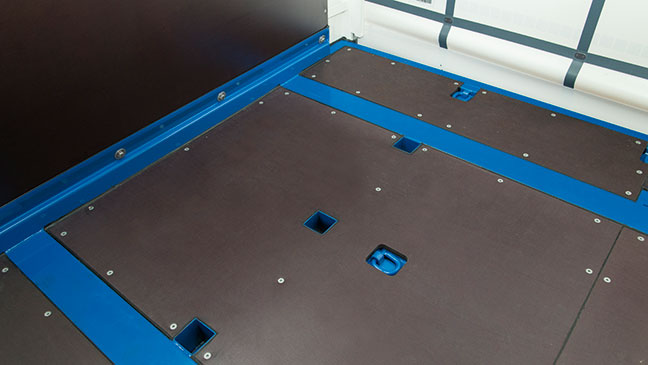

Five pairs of post sockets in the coil well and two plug-in posts are included in the standard equipment.

Vario Coil system

Using a grid rail on the beams along the coil trough, the Vario Coil system can be inserted flexibly along the whole length. This means that coils and slit strips of any size can be secured at the load's centre of gravity. Two coil securing supports with struts support the coil in the forwards direction , while one beam behind the coil secures it rearwards with the use of tension chains.

Weight optimisation

An optimised chassis, winchable aluminium landing legs and air tanks give the vehicle its low dead weight of 4,999 kg.

Heavy-duty strapping rings

Eight pairs of Heavy-duty strapping rings with a strapping load of 5,000 kg complement the many strapping points of the Multilock external frame

Post sockets in the neck area

In the neck area, the vehicle is fitted with additional post sockets as well as heavy-duty strapping rings. The front wall is clear to allow side loading

Curtain roller

The Coil Liner Compact can be fitted with a curtain roller to open the rear of the vehicle more quickly.

Location of the coil well

Five pairs of post sockets in the coil well and two plug-in posts are included in the standard equipment.

Telematics

KRONE's award-winning 3D telematics is the next evolutionary step in trailer telematics. Starting with the first dimension, KRONE offers high precision through its advanced telematics hardware and telematics portal. This allows customers to see exactly where their vehicles are. KRONE, a trailer manufacturer with years of expertise, offers a virtual twin of the trailer with all relevant data to support customers in their daily operations.

learn moreWarranty

Each new KRONE vehicle is delivered with a manufacturer's warranty. Our KRONE warranty extension allows you to extend the warranty period up to four years, because we are absolutely convinced of the quality of our vehicles. You can add this option directly at the time of purchase or in the following three months. The KRONE warranty extension can be purchased with Fair Care Complete.

learn moreSpare parts shop

The KRONE spare parts service - carriers must face many challenges and meet the highest standards of quality, reliability and care of a vehicle manufacturer as well as their products and services. KRONE considers service to be an obligation that does not end at the factory gate. At www.krone-trailerparts.com, you will find many accessories for your trailer, ranging from KRONE axle accessories to tool boxes.

learn moreFinancing

In logistics, flexibility is the decisive market advantage. This also applies to liquidity. That is why we offer you customised financing models, such as leasing, hire purchase or investment credit. You can easily increase your financial leeway when you need it.

learn moreFair Care

Planning and carrying out maintenance and wear-related repairs are time-consuming. Our Fair Care Service takes this work off your hands. Customise your individual service package for maintenance and wear-related repairs according to your needs, available with a term of 24 or up to 72 months. Depending on the contract module purchased, your KRONE Fair Care services include comprehensive services, such as vehicle maintenance including the replacement of wear parts, technical maintenance and the 24-hour breakdown service available in many countries.

learn more

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/5/csm_krone-megai-liner-comfort-freisteller_cd7ff2acaf.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/e/csm_krone-coil-compact-freisteller_a42a8fa25e.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/2/8/csm_krone-cool_liner_multitemp_freisteller_f9f7155d84.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/e/csm_krone-cool_liner_doppelstock_freisteller_4bf611bc7a.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/c/e/csm_krone-cool_liner_meathang_freisteller_df1c23c5a3.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/0/csm_krone_trailer_box_liner_eltu5_plus_fd6f92c531.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/1/csm_krone_trailer_box_liner_eltu5_2_1e7fc86956.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/4/csm_krone_trailer_box_liner_eltu4_a03c3c83c5.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/d/csm_krone-box-liner-sdc-27-el40_04b540a68b.png)

![[Translate to EN:] Profi Liner [Translate to EN:] Profi Liner](/fileadmin/_processed_/9/b/csm_krone-profi-liner-sdp-27-elb50-cs_47b1772edf.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/5/csm_krone-megai-liner-comfort-freisteller_dead48ff41.png)

![[Translate to EN:] Paper Liner [Translate to EN:] Paper Liner](/fileadmin/_processed_/0/1/csm_krone-paper-liner-freisteller_9bcbed63da.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/5/csm_krone-multi-steel-freisteller_22526b58b8.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/d/9/csm_krone-profi-liner-hd-freisteller_4c2435b435.png)